Integrated battery research: three trends of CTP, CTC and CTB

Basic concept of CTP, CTC and CTB

The traditional integration method of new energy vehicle power system is CTM, that is, "Cell to Module", which represents the mode of integrating battery cells on modules. The module is a development path for different models with different battery requirements and different battery cell sizes of battery manufacturers, which helps the formation of scaled economies and unified products. The general configuration is: battery cell - module - PACK - installed in vehicles; but such method only takes space utilization of 40%, largely limiting the space for other components. The development of battery integration (CTP, CTC, CTB) is gradually becoming the key research and application direction of the industry.

CTP is "Cell to Pack", which skips the standardized module and directly integrates battery cells into battery pack, which effectively improves space utilization and energy density of battery pack. This integration method was firstly proposed by CATL in 2019. Since then, BYD and SVOLT Energy have successively released their own CTP solutions. Among them, the more representative is BYD's "Blade" battery, which arranges individual battery cells together in an array, and then inserts them into the battery pack like a "blade", which is why everyone calls it a "blade battery".

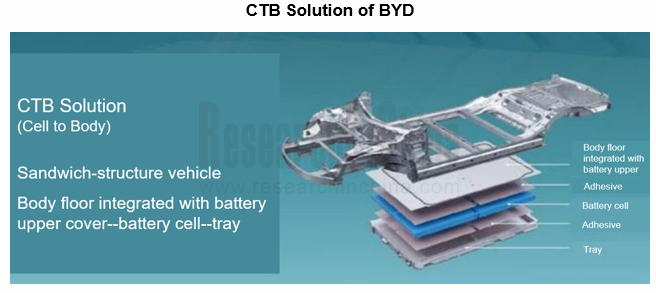

CTB (Cell to Body) is a new way of battery cell integration proposed by BYD to realize the transformation from body integration to battery-body integration, which helps to improve space utilization and further performance release of electric vehicles.

From the perspective of structural design, BYD's CTB technology combines body floor panel and the upper shell of battery pack into one, which is integrated into flat sealing surface formed by upper cover of battery, threshold and front and rear beams. The passenger cockpit is sealed with sealant, and the bottom is assembled with body through mounting point. That is, when designing and manufacturing battery pack, the battery system is integrated with body as a whole, sealing and waterproof requirements of the battery itself can be met, and sealing of battery and passenger cockpit is relatively simple, so the risk is controllable.

CTB technology is an extension of CTP technology, BYD's first CTB is more simplified and direct in structure, reducing the space loss caused by connection between body and battery cover, which is expected to further improve the overall space utilization. Under this structure, the battery is not only energy body, but also structural body to participate in force transmission and stress of the whole vehicle, which can reduce the intrusion of the side pillar by 45%.

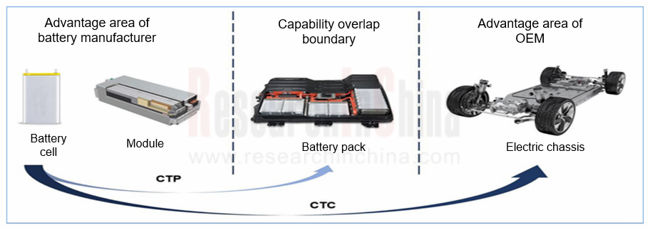

CTC (Cell to Chassis) is the process of integrating the battery cells directly into the vehicle chassis. It further deepens the integration of battery system with EV power system and chassis, reduces the number of components, saves space, improves structural efficiency, significantly reduces vehicle weight and increases battery range. The future stage of CTC will enable the matching efficiency to reach more than 90%, space utilization to reach more than 70%, and the number of components will be further reduced to about 400.

In September 2020, Tesla unveiled CTC technology at Battery Day. The battery cells or modules are installed in the body, connecting the front and rear body castings, and replacing cockpit floor with a battery upper cover. The technology is to be used in 2022 Model Y. Tesla predicts a 55% reduction in investment per GWH and a 35% reduction in space occupied with CTC technology.

CTC is not a simple extension of CTP, CTP does not break through PACK itself. Battery companies/professional PACK companies can complete development independently, but the technology does not extend downstream. The appearance of CTC will break limitation of PACK and directly involve the vehicle chassis, which is the most critical core component of the vehicle, and is the core advantage accumulated by OEMs through long-term development, which is difficult for battery companies/professional PACK companies to develop independently. Therefore, in terms of business model and cooperation mode, CTC and CTP have great differences.

The current CTC technology is still in the early stage of development. In the future, CTC technology will be deeply combined with skateboard chassis. In addition to the integration of battery system and chassis, electric drives, electronic controls, wire-controlled actuation components, and power domain controllers will all be highly integrated with chassis to further optimize power distribution, reduce energy consumption, improve production efficiency, reduce production costs and product development cycles, etc.

In 2022, the passenger car battery integration shows following trends.

Trend 1: Large-scale installation of CTP, CTC, CTB technologies in 2022

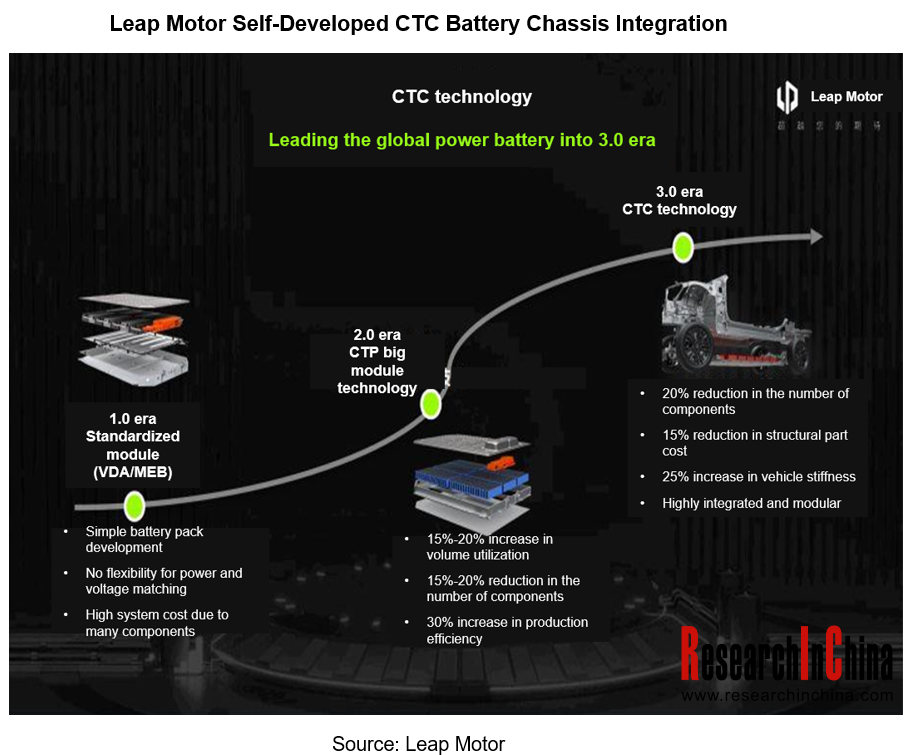

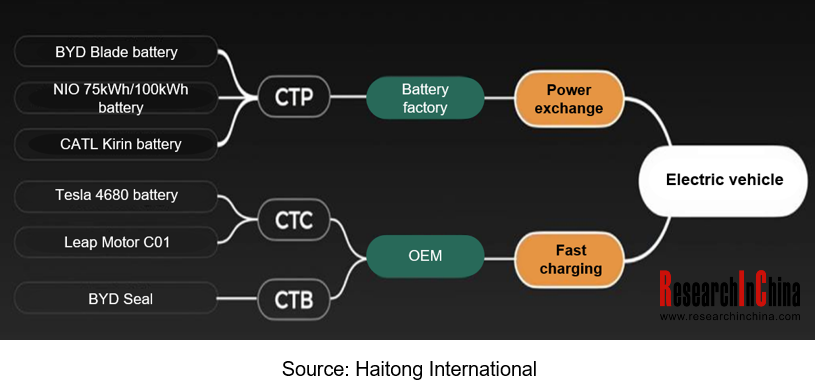

In 2022, CTP, CTC and CTB technologies achieve scale installation. Users of CATL CTP include Tesla Model 3/Y, Xpeng P7/G3, NIO ES6/ET7, Roewe RES33, Neta and many other models; Leap Motor released CTC battery-chassis integration and BYD launched CTB for Seal series.

With integration of new energy vehicles and the help of wire-controlled technology, the pattern of supply chain has been further reshaped. From the perspective of OEMs, the standard module technology advocated by VDA is the first-generation technology, CTP is the second generation, and various CTC, CTB, etc. are the third generation. From CTP to CTC/CTB, the dominance of OEMs is further enhanced.

The year 2022 is the first year of mass production of CTC technology, Tesla Model Y and Leap Motor C01 are the first to achieve mass production in the industry with their respective CTC technology.

Trend 2: New energy vehicle battery pack and chassis industry chain transfer to the battery factory

At present, battery companies have the voice over the new energy vehicle industry chain, which also means that the core value of OEMs has been weakened and the profit space has been greatly reduced. Powerful battery manufacturers take the opportunity to extend their capabilities to the field of chassis development.

CATL will officially launch its highly integrated CTC (Cell to Chassis) battery technology around 2025. Cai Jianyong, former general manager of intelligent vehicle control in Huawei Intelligent Vehicle Solutions BU, joined CATL and was in charge of CTC battery-chassis integration business.

According to CATL, the company will achieve integrated CTC by 2025 and intelligent CTC by 2030, in which the integrated CTC technology will not only rearrange batteries, but also include power components such as motors, electronic controls, DC/DC and OBCs. Intelligent CTC technology will further optimize power distribution and reduce energy consumption through intelligent power domain controllers.

Trend 3: Integration

The difference between modulization and integration lies in the way of energy replenishment: power exchange for modular CTP; fast charging for CTC/CTB. The more integrated CTC/CTB battery will be mainstream, and the integrated CTC/CTB route often has higher requirements for thermal management, and the importance of heat pump air conditioning is highlighted. The most technically aggressive BYD Seal has confirmed that it will be equipped with heat pump air conditioning thermal management system, and it is expected that heat pump air conditioning will become standard configuration in CTC/CTB models in the future.

Autonomous Driving Domain Controller and Central Computing Unit (CCU) Industry Report, 2025

Research on Autonomous Driving Domain Controllers: Monthly Penetration Rate Exceeded 30% for the First Time, and 700T+ Ultrahigh-compute Domain Controller Products Are Rapidly Installed in Vehicles

L...

China Automotive Lighting and Ambient Lighting System Research Report, 2025

Automotive Lighting System Research: In 2025H1, Autonomous Driving System (ADS) Marker Lamps Saw an 11-Fold Year-on-Year Growth and the Installation Rate of Automotive LED Lighting Approached 90...

Ecological Domain and Automotive Hardware Expansion Research Report, 2025

ResearchInChina has released the Ecological Domain and Automotive Hardware Expansion Research Report, 2025, which delves into the application of various automotive extended hardware, supplier ecologic...

Automotive Seating Innovation Technology Trend Research Report, 2025

Automotive Seating Research: With Popularization of Comfort Functions, How to Properly "Stack Functions" for Seating?

This report studies the status quo of seating technologies and functions in aspe...

Research Report on Chinese Suppliers’ Overseas Layout of Intelligent Driving, 2025

Research on Overseas Layout of Intelligent Driving: There Are Multiple Challenges in Overseas Layout, and Light-Asset Cooperation with Foreign Suppliers Emerges as the Optimal Solution at Present

20...

High-Voltage Power Supply in New Energy Vehicle (BMS, BDU, Relay, Integrated Battery Box) Research Report, 2025

The high-voltage power supply system is a core component of new energy vehicles. The battery pack serves as the central energy source, with the capacity of power battery affecting the vehicle's range,...

Automotive Radio Frequency System-on-Chip (RF SoC) and Module Research Report, 2025

Automotive RF SoC Research: The Pace of Introducing "Nerve Endings" such as UWB, NTN Satellite Communication, NearLink, and WIFI into Intelligent Vehicles Quickens

RF SoC (Radio Frequency Syst...

Automotive Power Management ICs and Signal Chain Chips Industry Research Report, 2025

Analog chips are used to process continuous analog signals from the natural world, such as light, sound, electricity/magnetism, position/speed/acceleration, and temperature. They are mainly composed o...

Global and China Electronic Rearview Mirror Industry Report, 2025

Based on the installation location, electronic rearview mirrors can be divided into electronic interior rearview mirrors (i.e., streaming media rearview mirrors) and electronic exterior rearview mirro...

Intelligent Cockpit Tier 1 Supplier Research Report, 2025 (Chinese Companies)

Intelligent Cockpit Tier1 Suppliers Research: Emerging AI Cockpit Products Fuel Layout of Full-Scenario Cockpit Ecosystem

This report mainly analyzes the current layout, innovative products, and deve...

Next-generation Central and Zonal Communication Network Topology and Chip Industry Research Report, 2025

The automotive E/E architecture is evolving towards a "central computing + zonal control" architecture, where the central computing platform is responsible for high-computing-power tasks, and zonal co...

Vehicle-road-cloud Integration and C-V2X Industry Research Report, 2025

Vehicle-side C-V2X Application Scenarios: Transition from R16 to R17, Providing a Communication Base for High-level Autonomous Driving, with the C-V2X On-board Explosion Period Approaching

In 2024, t...

Intelligent Cockpit Patent Analysis Report, 2025

Patent Trend: Three Major Directions of Intelligent Cockpits in 2025

This report explores the development trends of cutting-edge intelligent cockpits from the perspective of patents. The research sco...

Smart Car Information Security (Cybersecurity and Data Security) Research Report, 2025

Research on Automotive Information Security: AI Fusion Intelligent Protection and Ecological Collaboration Ensure Cybersecurity and Data Security

At present, what are the security risks faced by inte...

New Energy Vehicle 800-1000V High-Voltage Architecture and Supply Chain Research Report, 2025

Research on 800-1000V Architecture: to be installed in over 7 million vehicles in 2030, marking the arrival of the era of full-domain high voltage and megawatt supercharging.

In 2025, the 800-1000V h...

Foreign Tier 1 ADAS Suppliers Industry Research Report 2025

Research on Overseas Tier 1 ADAS Suppliers: Three Paths for Foreign Enterprises to Transfer to NOA

Foreign Tier 1 ADAS suppliers are obviously lagging behind in the field of NOA.

In 2024, Aptiv (2.6...

VLA Large Model Applications in Automotive and Robotics Research Report, 2025

ResearchInChina releases "VLA Large Model Applications in Automotive and Robotics Research Report, 2025": The report summarizes and analyzes the technical origin, development stages, application cases...

OEMs’ Next-generation In-vehicle Infotainment (IVI) System Trends Report, 2025

ResearchInChina releases the "OEMs’ Next-generation In-vehicle Infotainment (IVI) System Trends Report, 2025", which sorts out iterative development context of mainstream automakers in terms of infota...