Global and China Li-ion Power Battery Industry Report, 2014-2016

-

Sep.2014

- Hard Copy

- USD

$2,800

-

- Pages:195

- Single User License

(PDF Unprintable)

- USD

$2,600

-

- Code:

YS002

- Enterprise-wide License

(PDF Printable & Editable)

- USD

$4,100

-

- Hard Copy + Single User License

- USD

$3,000

-

In 2013, the sales volume of global electric vehicles reached 228,000 vehicles, including 95,000 PHEVs and 133,000 BEVs. With the further promotion of electric vehicles globally, the sales volume will rise to 700,000 vehicles by 2016.

The global demand for electric vehicle power batteries came to 5,662MWh in 2013; however, following the rising electric vehicle sales and battery capacity per vehicle, the figure is expected to climb to 31,100MWh by 2016.

Currently, the global power batteries develop mainly in the following three technology roadmaps:

(1) Manganese-based. This type of batteries uses LMO as cathode materials. Typically, however, after modification treatment, they are mixed with a small amount of NCM or LNO to increase their energy density. This is mainly represented by the foreign companies—including LGC, AESC, and LEJ, as well as the Chinese company CITIC GUOAN MGL. Now, this has become the mainstream technology roadmap in the field of global electric vehicles.

(2) Ternary materials-based. This mainly takes NCA and NCM as cathode materials. NCM-based batteries have high energy density, but with higher costs than that of LMO batteries. The typical companies consist of SDI and SKI from abroad and the Chinese Lishen and Wangxiang Group, etc. NCA adopts 18650-type battery, which is mainly used in Tesla, with the highest energy density for now. But because of poor safety performance, the advanced BMS is needed to monitor the operating condition of the battery. Thus, the battery has not been widely used.

(3) LFP-based. Canada and the United States were the first to develop power battery technology, with main patent owners including the U.S. Valence, A123 and University of Texas, and the Canadian Phostech and Hydro-Quebec. On the other hand, there are numerous power battery companies in China such as BYD and Hefei Guoxuan High-Tech Power Energy Co.,Ltd that adopt the LFP technology, but the LFP battery has many problems and was not made available around the world.

At present, manganese-series power battery consisting of NCM and LMO occupies the mainstream status on a global scale, with the cost of battery pack generally higher than USD600/kWh; the lower-cost NCA 18650 batteries fail to be popular with automakers due to safety issues; the similarly lower-cost LFP batteries, because of the poor comprehensive performance, are only popularized and used in China and the United States, while the U.S. automakers have gradually abandoned LFP batteries and turned on purchasing Mn-series batteries from Japanese and S. Korean companies.

There is no major technological breakthrough yet in power battery. The main driving factors for power battery price collapses are expected to come from the material cost reduction and scale effect, with relatively limited downslide potential.

China’s power battery shipments reached 533MWh in 2013, which increased by 61% year on year and accounted for less than 10% of the world’s total. At present the main demand comes from electric city bus. As the charging facilities are not perfect in China, the private electric passenger cars are rarely sold.

In terms of power battery companies, BYD and Guoxuan High-Tech have the shipments that have far exceeded those of their rivals. And BYD batteries are mainly used to support its own electric passenger cars and buses while Guoxuan High-Tech supplies batteries to JAC, Ankai Bus and other auto makers.

For power battery companies, winning the support of big carmakers is of the utmost importance from a global perspective. It is projected that electric buses will still be the main driving forces behind the development of China's power battery market for some time to come. How to penetrate the electric bus supply chain seems crucial.

Global and China Li-ion Power Battery Industry Report , 2014-2016 by ResearchInChina mainly covers the followings:

Analysis of industry chain, including the key materials, Cells, Pack & BMS, etc.;

Analysis of industry chain, including the key materials, Cells, Pack & BMS, etc.;

Analysis of technology roadmap, including battery cost, performance, and development directions, etc.;

Analysis of technology roadmap, including battery cost, performance, and development directions, etc.;

Market size, sales volume ,supply relationship, etc. of global and Chinese electrical vehicle industry;

Market size, sales volume ,supply relationship, etc. of global and Chinese electrical vehicle industry;

Shipment, market size, price, supply relationship, etc. of global and Chinese Li-ion Power Battery industry.

Shipment, market size, price, supply relationship, etc. of global and Chinese Li-ion Power Battery industry.

Operation, technology, development plan, production & marketing of nine lithium battery separator companies in the world, mainly of Korea, Japan and USA

Operation, technology, development plan, production & marketing of nine lithium battery separator companies in the world, mainly of Korea, Japan and USA

Operation, technology, development plan, production & marketing of ten lithium battery separator companies in China.

Operation, technology, development plan, production & marketing of ten lithium battery separator companies in China.

1. Introduction to Power Lithium Battery

1.1 Power Battery Classification

1.2 Power Cell Structure

2. Power Lithium Battery Industry Chain Analysis

2.1 Industry Overview

2.2 Critical Materials

2.2.1 Cathode Materials

2.2.2 Anode Materials

2.2.3 Separator

2.2.4 Electrolyte

2.3 Cell

2.3.1 Cell Cost

2.3.2 Cell Capacity

2.3.3 Cell Structure

2.3.4 Supply Relationship

2.4 PACK+BMS

2.4.1 Battery Costs

2.4.2 BMS

2.5 Technology Roadmap

2.5.1 Cost Analysis

2.5.2 Selection of Technology Roadmap

2.5.3 Technology Trends

3. Global Electric Vehicle Market

3.1 Classification

3.1.1 Micro Hybrid (u-HEV)

3.1.2 Hybrid (HEV)

3.1.3 Plug-in Hybrid (PHEV)

3.1.4 Electric Vehicle (EV)

3.2 Global EV Market

3.2.1 Overview

3.2.2 USA

3.2.3 Europe

3.2.4 Japan

3.3 EV Market in China

3.3.1 Overview

3.3.2 Bus Market

3.4 Electric Vehicle Models

4. Global Power Lithium Battery Industry

4.1 Global Power Lithium Battery Industry

4.1.1 Demand

4.1.2 Price

4.1.3 Market Size

4.2 China Power Lithium Battery Industry

4.2.1 Demand

4.2.2 Price

4.2.3 Market Size

4.3 Power Lithium Battery Companies

4.3.1 Market Share

4.3.2 Supporting Relationship

5. Major Power Lithium Battery Manufacturers in Korea

5.1 LG Chemical

5.1.1 Profile

5.1.2 Battery Technology

5.1.3 Business Development and Outlook

5.1.4 Customer Analysis

5.1.5 Business Layout in China

5.1.6 Capacity and Output

5.2 SDI

5.2.1 Profile

5.2.2 Battery Technology

5.2.3 Business Development and Outlook

5.2.4 Customer Analysis

5.2.5 Business Layout in China

5.2.6 Capacity and Output

5.3 SK Innovation

5.3.1 Profile

5.3.2 Battery Technology

5.3.3 Development and Prospect

5.3.4 Business in China

5.3.5 Capacity and Output

6. Lithium-ion Power Battery Companies in Japan

6.1 Panasonic

6.1.1 Profile

6.1.2 Battery Technology

6.1.3 Business Development and Prospect

6.1.4 Business Layout in China

6.1.5 Customer Analysis

6.1.6 Capacity and Output

6.2 AESC

6.2.1 Profile

6.2.2 Battery Technology

6.2.3 Business Development and Outlook

6.2.4 Layout in China

6.2.5 Capacity and Output

6.3 LEJ

6.3.1 Profile

6.3.2 Battery Technology

6.3.3 Business Development and Outlook

6.3.4 Customer Analysis

6.3.5 Capacity and Output

7. Major Power Lithium Battery Manufacturers in Europe and America

7.1 Li-Tec&Accumotive

7.1.1 Profile

7.1.2 Battery Technology

7.1.3 Business Development and Outlook

7.1.4 Customer Analysis

7.2 A123

7.2.1 Profile

7.2.2 Operation

7.2.3 Subsidiaries in China

7.3 Valence

7.3.1 Profile

7.3.2 Operation

7.3.3 Latest Products

7.3.4 Subsidiaries in China

8. Major Chinese Power Battery Companies

8.1 Hefei Guoxuan High-tech Power Energy Co., Ltd

8.1.1 Profile

8.1.2 Battery Technology

8.1.3 Business Development and Prospects

8.1.4 Customers

8.1.5 Capacity and Output

8.2 BYD Company Co., LTD

8.2.1 Profile

8.2.2 Battery Technology

8.2.3 Application Fields

8.2.4 Customer Analysis

8.2.5 Capacity and Output

8.3 Beijing Pride Power System Technology

8.3.1 Profile

8.3.2 Technology

8.3.3 Business Development and Outlook

8.3.4 Customers

8.3.5 Capacity and Output

8.4 Tianjin Lishen Battery Joint-Stock Co., Ltd.

8.4.1 Profile

8.4.2 Battery Technology

8.4.3 Business Development and Outlook

8.4.4 Customers

8.4.5 Capacity and Output

8.5 China BAK Battery, Inc.

8.5.1 Profile

8.5.2 Battery Technology

8.5.3 Business Development and Outlook

8.5.4 Customers

8.5.5 Capacity and Output

8.6 Wanxiang EV

8.6.1 Profile

8.6.2 Battery Technology

8.6.3 Business Development and Outlook

8.6.4 Customers

8.7 Sinopoly Battery

8.7.1 Profile

8.7.2 Battery Technology

8.7.3 Business Development and Prospect

8.7.4 Customers

8.7.5 Capacity and Output

8.8 CITIC GUOAN Mengguli

8.8.1 Profile

8.8.2 Battery Technology

8.8.3 Business Development and Outlook

8.8.4 Capacity and Output

8.9 China Aviation Lithium Battery

8.9.1 Profile

8.9.2 Battery Technology

8.9.3 R&D

8.9.4 Business Development and Outlook

8.9.5 Customers

8.9.6 Capacity and Output

8.10 Amperex Technology

8.10.1 Profile

8.10.2 Battery Technology

8.10.3 Business Development and Outlook

Power-type and Capacity-type Power Lithium Battery Classification

Prismatic Cell Structure

Cylindrical Cell Structure

Pouch Cell Structure

Power Lithium Battery Value Chain

Power Lithium Battery Production Process

Working Principle of Lithium Battery

Cost Structure of Lithium Battery

Shipment of Global Cathode Materials (by Product), 2006-2014

Chinese Cathode Material Price, 2010-2014

Market Share of Global Cathode Material Enterprises, 2013

Output Structure of Global Anode Materials, 2013

Market Share of Global Anode Material Enterprises, 2013

Technical Feature Comparison among Several Anode Materials

Common Electronics and Automobiles’ Consumption of Lithium Battery Separator

Global Shipment of Ordinary and High-performance Lithium Battery Separator, 2008-2016E

Global Separator Price, 2008-2016

Market Share of Global Lithium Battery Separator Enterprises, 2013

Global Power Battery Supporting Separator, 2013

Shipment of Global Lithium Battery Electrolyte, 2011-2016

Cost Structure of Lithium Battery Electrolyte

Market Share of Global LiPF6 Enterprises, 2013

Global LiPF6 Price, 2009-2016E

Market Share of Global Electrolyte Enterprises, 2013

Cost Structure of Lithium Battery Cells in China

Cost Reduction Trend of Lithium Battery Cells in China

Cells Used on Major Electrical Vehicle Models Worldwide, 2013

Single Cell Capacity Distribution of Mainstream Electric Vehicles Worldwide (Ah), 2013

Battery Structure of Mainstream Electric Vehicles Worldwide

Supply Chain of Key Materials of Global Cell Manufacturers, 2013

Supply Chain of Key Materials of Global Cell Manufacturers, 2013

Cost Decomposition of Lithium Battery Pack

Global Electric Vehicle Battery Technologies, Suppliers and Costs, 2013

The Falling Trend of Battery Cost of Tesla Model S

Major BMS Suppliers for Electrical Vehicles Worldwide

Metal Content of Cathode Materials in Different Technology Roadmaps

Cost Analysis of Cathode Materials in Different Technology Roadmaps

Performance of Lithium-Ion Battery Packs in Different Technology Roadmaps

Life Cycle of Cathode Material Products

Specifications of Cathode Materials in Different Technology Roadmaps

Development Trend in New Cathode Materials

Chemical Structure of Laminar Lithium-Rich Manganese-based Cathode Materials

Sales Volume of Global EVs by Country, 2013

Sales Volume of Global EVs, 2008-2016E

Sales Volume of EVS in the US by Model, 2013

Sales Volume of EVS in Europe by Model, 2013

Sales Volume of EVs in Japan by Model, 2013

Sales Volume of EVs in China, 2008-2016E

Proportion of China’s EVs in Global Total by Sales Volume, 2008-2016E

Plan for Promotion of EVs in China, 2014-2015E

Sales Volume of Electric City Buses and % of City Buses in China, 2009-2016E

Sales Volume of Electric Buses in China by Enterprise, 2012-2016E

Investment of Electric Buses in China, 2009-2014

Sales Volume of 40 Global Electric Passenger Vehicle Models, 2011-2013

Battery Capacity and Battery Life for 40 Global Electric Vehicle Models, 2013

Global EV Battery Capacity per Car, 2008-2016E

Global Demand for Automotive Battery, 2008-2016E

Global Lithium Battery Shipments (by Demand), 2008-2016E

Battery Pack Cost of Global Major EVs, 2013

Global Power Lithium Battery Pack Price, 2008-2016E

Global Power Lithium Battery Industry Scale, 2008-2016E

Global Lithium Battery Industry Scale, 2008-2016E

China’s Demand for Automotive Battery, 2011-2016E

China Power Lithium Battery Pack Price, 2008-2016E

China Power Lithium Battery Industry Scale, 2010-2016E

China Lithium Battery Industry Scale, 2008-2016E

Market Share of Battery Companies Supporting Global 40 EV Models, 2013

Shipments of Batteries for Global 40 EV Models, 2013

Market Share of Global Small Lithium Battery Companies, 2013

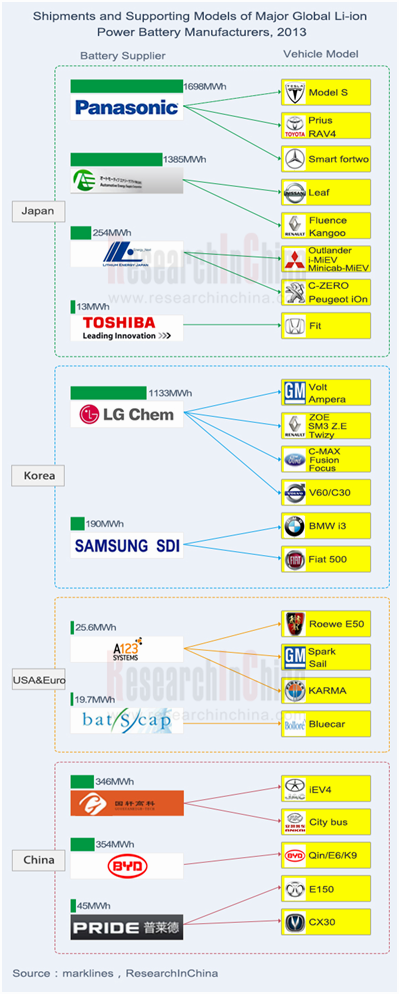

EU and US Power Lithium Battery Companies and Their Supported Models

S. Korean Power Lithium Battery Companies and Their Supported Models

Japanese Power Lithium Battery Companies and Their Supported Models

Chinese Power Lithium Battery Companies and Their Supported Models

Equity Structure of LGC, 2013

Operating Performance of LGC, 2007-2014Q2

Revenue of LGC by Region, 2013

Revenue Structure of LGC, 2012-2013

Material Costs Structure of LGC's PHEV Cel

LGC Road Map for HEV LIB Technology

LGC Road Map for PHEV LIB Technology

LGC Road Map for EV LIB Technology

Business Development and Outlook of LGC's Lithium Business

Operating Performance of LGCPI, 2010-2014

Operating Performance of HL Green Power, 2010-2014

Operating Performance of LGC's Battery Business, 2013Q1-2014Q2

Electrical Vehicles Supported by LGC's Power Lithium Batteries

Managing Organizations of LGC in China

Production and Sales Network of LGC in China

Shipment of LGC's Power and Energy Storage Batteries, 2011-2014 (MWh)

Equity Structure of SDI, 2013

Operating Performance of SDI, 2008-2014Q2

Revenue of SDI by Region, 2013

SDI Road Map for xEV LIB Technology

Technical Performance of SDI's Power Lithium Batteries

Development and Operating Performance of SDI's Battery Business, 2007-2014Q2

SDI's Battery Shipments and Average Selling Price, 2007-2014

SDI's Revenue of Power Batteries, 2013Q1-2014Q2

Electric Vehicles Supported by SDI's Power Lithium Batteries

SDI's Shipment of Power and Energy Storage Batteries (MWh), 2011-2014

Major Subsidiaries of SKI

Supported EV Models of SKI’s Lithium Power Battery

Equity Structure of BESK

Profile of BESK

Specifications of BESK’s Lithium Power Battery

Output, Capacity, and Capacity Ulitilization Rate of SKI’s Battery Material (Separator), 2009-2013

Operation Performance of Panasonic, FY2008/09- FY2013/14

R & D Costs of Panasonic, FY2008/09-FY2013/14

Revenue Breakdown of Panasonic by Segment, FY2008-FY2013

Operating Profit Breakdown of Panasonic by Segment, FY2008-FY2013

Revenue Breakdown of Panasonic by Region, FY2013

Specifications of Panasonic’s NCA 18650 Cell Applied in Tesla

Cost Strucuture of Panasonic’s PHEV Cell

Developemnt Plan of Panasonic’s Automotive Batteries, FY2013-FY2019

Development Plan of Panasonic’s Automobile Segment, FY2013- FY2019

Developemnt Plan of Panasonic by Segment, FY2013-FY2019

Supported Electric Vehicles of Panasonic’s Lithium-ion Power Battery

Deliveries of Tesla’s Electric Vehicle, 2010-2016

Shipment of Panasonic’s Power Battery and Energy-storage Battery (MWh), 2011-2014

Equity Structure of AESC, 2013

Costs Structure of AESC BEV Cell Materials

AESC Power Lithium-ion Battery Module Structure

Specifcication and Connecton of AESC High-capacity Power Battery

Performance Parameter of AESC High-capacity Power Battery

Specifcication and Connection of AESC High Power Battery

Performance Parameter of AESC High Power Battery

AESC Power Battery System Solutions

Supporting Electric Vehicles of AESC Power Lithium-Ion Battery

Shipments of AESC Power and Energy Storage Battery (MWh), 2011-2014E

Equity Structure of LEJ, 2013

Specifications of LEJ Power Lithium Batteries

Electric Vehicles Supported by LEJ's Power Lithium Batteries

LEJ's Shipment of Power and Energy Storage Batteries (MWh), 2011-2014

Specifications of Li-Tec's High-Capacity Power Batteries

Performance Parameters of Li-Tec's High-Capacity Power Batteries

Li-Tec's Power Battery Plant in Kamenz, Germany

History of A123Systems

Revenue and Gross Profit of A123Systems, FY2007- FY2012

Electric Vehicles Supported by A123's Power Lithium Batteries

Revenue of Subsidiaries of A123Systems in China

Project Investment of Changzhou Gaobo, 2005-2008

Revenue and Net Profit of Valence, FY2008-FY2012

Operation of Valence’s Subsidiaries in China

Equity Structure of Guoxuan

Operating Performance of Guoxuan, 2009-2013

Technical Parameters for Guoxuan’s LFP Cathode Materials

Specification Parameters for Guoxuan’s LFP Power Cells

Technical Parameters for Models Supported by Guoxuan’s Power Batteries

Power/Energy Storage Battery Output, Capacity and Capacity Utilization of Guoxuan, 2009-2013

Capacity and Investment Plan of Guoxuan, 2009-2013

Operating Performance of BYD, 2008-2013

Revenue Structure of BYD (by Business), 2012-2013

Gross Margin of BYD (by Business), 2009-2013

Major Characteristics of BYD Lithium Iron Phosphate Battery

Capacity, Weight and Cost of BYD Automotive Battery Pack

Lithium Battery Capacity and Weight of BYD Electric Forklifts

Lithium Battery Capacity of BYD ESS

Lithium Battery Capacity of BYD EPS

Sales Volume of BYD Electric Vehicle (by Model), Jan. 2013-May 2014

Sales Volume of BYD Electric Vehicles, 2011-2017

Battery Demand of BYD Electric Vehicle (MWh), 2011-2017

Output, Capacity and Capacity Utilization of BYD Power and Storage Battery, 2011-2017

Equity Structure of Pride, 2013

Operating Performance of Pride, 2011-2013

Performance Parameters of Pride’s Power Battery Pack

Equity Structure of Lishen

Operating Performance of Lishen, 2011-2013

Technology Roadmap for Power Cell of Lishen

Technology Roadmap for Power Battery Pack of Lishen

Performance Parameters of Spiral Wound Power Cell of Lishen

Performance Parameters of Laminated Power Cell of Lishen

Performance Parameters of Polymer Power Cell of Lishen

Technical Parameters of Power Cell of Lishen

Customers of Lishen’s Power Battery

Performance Parameters of Power Battery Pack of Lishen

Lithium Battery Capacity of Lishen, 2000-2013

Investment Plan for Power Battery of Lishen, 2012-2014

Operating Performance of CHINA BAK BATTERY, 2008-Q1 2014

Revenue Structure of CHINA BAK BATTERY (by Regions), 2009-2013

R & D Costs and % of Total Revenue of China BAK Battery, 2010-2013

Technical Parameters of Power Cell of China BAK Battery

Basic Information of BAK International (Tianjin) Limited

Basic Information of BAK Power Battery (Dalian)

Sales of High-power Lithium Battery Cells of China BAK Battery, 2009-2013

Investment Plan of High-power Lithium Battery Cells of China BAK Battery, 2013-2014

Revenue and Gross Margin of Sinopoly Battery, 2011-2013

Net Income of Sinopoly Battery, 2011-2013

Specifications of Sinopoly’s Power Cell

Operating Results of CITIC GUOAN Mengguli, 2009-2013

Technical Parameters of Cathode Materials of CITIC GUOAN Mengguli

Technical Parameters of Power Battery Modules of CITIC GUOAN Mengguli

Equity Structure of China Aviation Lithium Battery, 2013

Operating Results of China Aviation Lithium Battery, 2010-2013

Pure Electric Vehicle BMS of China Aviation Lithium Battery

Battery Certification of China Aviation Lithium Battery

Global Marketing Network of China Aviation Lithium Battery

Major Customers of China Aviation Lithium Battery

Basic Information of Amperex Technology Limited

Autonomous Driving Domain Controller and Central Computing Unit (CCU) Industry Report, 2025

Research on Autonomous Driving Domain Controllers: Monthly Penetration Rate Exceeded 30% for the First Time, and 700T+ Ultrahigh-compute Domain Controller Products Are Rapidly Installed in Vehicles

L...

China Automotive Lighting and Ambient Lighting System Research Report, 2025

Automotive Lighting System Research: In 2025H1, Autonomous Driving System (ADS) Marker Lamps Saw an 11-Fold Year-on-Year Growth and the Installation Rate of Automotive LED Lighting Approached 90...

Ecological Domain and Automotive Hardware Expansion Research Report, 2025

ResearchInChina has released the Ecological Domain and Automotive Hardware Expansion Research Report, 2025, which delves into the application of various automotive extended hardware, supplier ecologic...

Automotive Seating Innovation Technology Trend Research Report, 2025

Automotive Seating Research: With Popularization of Comfort Functions, How to Properly "Stack Functions" for Seating?

This report studies the status quo of seating technologies and functions in aspe...

Research Report on Chinese Suppliers’ Overseas Layout of Intelligent Driving, 2025

Research on Overseas Layout of Intelligent Driving: There Are Multiple Challenges in Overseas Layout, and Light-Asset Cooperation with Foreign Suppliers Emerges as the Optimal Solution at Present

20...

High-Voltage Power Supply in New Energy Vehicle (BMS, BDU, Relay, Integrated Battery Box) Research Report, 2025

The high-voltage power supply system is a core component of new energy vehicles. The battery pack serves as the central energy source, with the capacity of power battery affecting the vehicle's range,...

Automotive Radio Frequency System-on-Chip (RF SoC) and Module Research Report, 2025

Automotive RF SoC Research: The Pace of Introducing "Nerve Endings" such as UWB, NTN Satellite Communication, NearLink, and WIFI into Intelligent Vehicles Quickens

RF SoC (Radio Frequency Syst...

Automotive Power Management ICs and Signal Chain Chips Industry Research Report, 2025

Analog chips are used to process continuous analog signals from the natural world, such as light, sound, electricity/magnetism, position/speed/acceleration, and temperature. They are mainly composed o...

Global and China Electronic Rearview Mirror Industry Report, 2025

Based on the installation location, electronic rearview mirrors can be divided into electronic interior rearview mirrors (i.e., streaming media rearview mirrors) and electronic exterior rearview mirro...

Intelligent Cockpit Tier 1 Supplier Research Report, 2025 (Chinese Companies)

Intelligent Cockpit Tier1 Suppliers Research: Emerging AI Cockpit Products Fuel Layout of Full-Scenario Cockpit Ecosystem

This report mainly analyzes the current layout, innovative products, and deve...

Next-generation Central and Zonal Communication Network Topology and Chip Industry Research Report, 2025

The automotive E/E architecture is evolving towards a "central computing + zonal control" architecture, where the central computing platform is responsible for high-computing-power tasks, and zonal co...

Vehicle-road-cloud Integration and C-V2X Industry Research Report, 2025

Vehicle-side C-V2X Application Scenarios: Transition from R16 to R17, Providing a Communication Base for High-level Autonomous Driving, with the C-V2X On-board Explosion Period Approaching

In 2024, t...

Intelligent Cockpit Patent Analysis Report, 2025

Patent Trend: Three Major Directions of Intelligent Cockpits in 2025

This report explores the development trends of cutting-edge intelligent cockpits from the perspective of patents. The research sco...

Smart Car Information Security (Cybersecurity and Data Security) Research Report, 2025

Research on Automotive Information Security: AI Fusion Intelligent Protection and Ecological Collaboration Ensure Cybersecurity and Data Security

At present, what are the security risks faced by inte...

New Energy Vehicle 800-1000V High-Voltage Architecture and Supply Chain Research Report, 2025

Research on 800-1000V Architecture: to be installed in over 7 million vehicles in 2030, marking the arrival of the era of full-domain high voltage and megawatt supercharging.

In 2025, the 800-1000V h...

Foreign Tier 1 ADAS Suppliers Industry Research Report 2025

Research on Overseas Tier 1 ADAS Suppliers: Three Paths for Foreign Enterprises to Transfer to NOA

Foreign Tier 1 ADAS suppliers are obviously lagging behind in the field of NOA.

In 2024, Aptiv (2.6...

VLA Large Model Applications in Automotive and Robotics Research Report, 2025

ResearchInChina releases "VLA Large Model Applications in Automotive and Robotics Research Report, 2025": The report summarizes and analyzes the technical origin, development stages, application cases...

OEMs’ Next-generation In-vehicle Infotainment (IVI) System Trends Report, 2025

ResearchInChina releases the "OEMs’ Next-generation In-vehicle Infotainment (IVI) System Trends Report, 2025", which sorts out iterative development context of mainstream automakers in terms of infota...