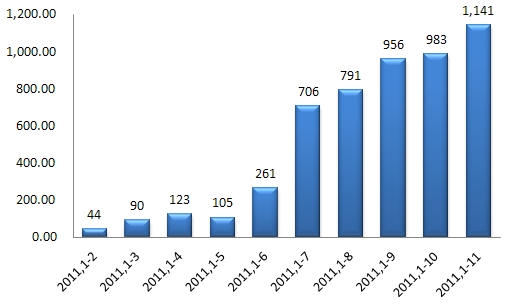

During the period of January to November in 2011, 32 special steel enterprises produced 1,141,356 tons of mould steel, up 3.34% from 1,104,497 tons of 2010 over the same period. In November, the total output of 32 enterprises accumulated to 158,803 tons, which grew by nearly 5 times against the output of 26,839 tons in October, but down 5% compared to 167,147 tons in November 2010.

Output of Mould Steel of 32 Special Steel Enterprises in China, Jan.-Nov. 2011

Source: Mysteel, ResearchInChina

It is expected that demand of plastic mould steel, large scale mould steel and medium to high-end mould steel will constantly increase in the next five years.

-

Automotive and home appliance is the main application market of plastic mould steel. Over 90% of the auto parts are molded, which uses cold forming, hot forming and plastic mould steel. Mould consumption of every 10,000 cars reaches 0.12 tons. 80% components of home appliance rely on molding, wherein consumption of plastic mould steel is the most.

-

On one hand, mould forming component follows the trend of large-scaled; on the other hand, to enhance production efficiency, one-mold and multi-cavity model is widely used; thus, demand of large scale mould steel will increase year by year.