Global and China Lithium Battery Separator Industry Report, 2017-2022

-

Sep.2017

- Hard Copy

- USD

$3,200

-

- Pages:190

- Single User License

(PDF Unprintable)

- USD

$3,000

-

- Code:

LT037

- Enterprise-wide License

(PDF Printable & Editable)

- USD

$4,500

-

- Hard Copy + Single User License

- USD

$3,400

-

Separator, as the one with highest technical barrier among four major raw materials of lithium battery, is the only remainder that still has not been completely made in China yet, particularly the wet-process separator which has been much sought after over the recent years. Howbeit, the gap between demand and supply is narrowing amid the technological advancement and capacity expansion of Chinese separator enterprises. In 2016, China’s output of separators posted 929 million m2, an upsurge of 33.03% on an annualized basis, and seeing a rising share of 56% in global total. The localization rate of separators was lifted to 79% in China in 2016, but the high-end separators still relied upon imports.

In the past five year, the average price of home-made 16μm wet-process separator fell from 9.5 yuan/m2 in 2010 to 5 yuan/m2 in 2016; and that of 16μm dry-process separator dived from 7.5 yuan/m2 in 2010 to 3-4 yuan/m2 in 2016. The slump in price is mainly caused by rapid capacity expansion of low- and medium-end separators as well as the price war staged by players to seize more market share. Furthermore, there are low- and medium-end overcapacity and disorderly competition in the downstream battery cell industry, which brings room for low-end low-priced separators.

Although the huge low-end capacity (mainly dry-process separator) of Chinese separator manufacturers lowered the average selling price of separators worldwide in the past five years, the demand for high-end wet-process separators will see explosive growth along with the continuously growing demand for power battery in the world, and the separator firms with low technical level and small production scale will be ultimately eliminated. Since 2017, separators of all kinds, without exception, have experienced fall in price, while high-end wet-process and dry-process separators saw a narrow decrease in price. Nevertheless, the high-end dry-process separator has small production capacity and finds limited application. Being with a descending trend, global separator price drop will be substantially narrowed compared with the fall during 2014-2016, mainly because the wet-process sees a rising proportion as wet-process separators accelerate to be used instead of dry-process ones in power battery.

In 2016, Shenzhen Senior Technology Material sold 120 million m2 of dry-process separators, ranking first in China, followed by Cangzhou Mingzhu Plastic Co., Ltd and Xinxiang Zhongke Science and Technology (GREEN) Co., Ltd. In 2016, the sales leader of wet-process separator came to Shanghai Energy New Materials Technology Co., Ltd, and it sold 100 million m2, with customers covering Samsung, LG, BYD, CATL, etc. In 2016, the top three by wet-process separator sales in China were Shanghai Energy New Materials Technology Co., Ltd, Suzhou GreenPower New Energy Materials Co., Ltd, and Foshan Jinhui Hi-tech Optoelectronic Material Co., Ltd.

Against the growing demand for wet-process separator in recent years, Chinese wet-process separator manufacturers are expanding production capacity aggressively and the originally dry-process separator producers also have made investments in wet-process separator production lines. At the end of 2016, Suzhou GreenPower New Energy Materials Co., Ltd is the Chinese producer with the biggest wet-process separator capacity up to 204 million m2. Besides, the dry-process leaders Xinxiang Zhongke Science and Technology (GREEN) Co., Ltd and Shenzhen Senior Technology Material Co., Ltd built some wet-process separator capacity, adding their separator capacity to total 170 million m2 and 156 million m2 respectively at the end of 2016.

Global and China Lithium Battery Separator Industry Report, 2017-2022 by ResearchInChina highlights the following:

Lithium battery separator production process, key technologies, and technology orientations;

Lithium battery separator production process, key technologies, and technology orientations;

Shipments, import volume, market size, prices, etc. of global and Chinese lithium battery separator industries;

Shipments, import volume, market size, prices, etc. of global and Chinese lithium battery separator industries;

Market shares, production process, capacity, supply relation, etc. of global and Chinese lithium battery separator companies;

Market shares, production process, capacity, supply relation, etc. of global and Chinese lithium battery separator companies;

Shipments of ordinary lithium battery and power battery, market size and analysis of battery cell manufacturers in China and the world;

Shipments of ordinary lithium battery and power battery, market size and analysis of battery cell manufacturers in China and the world;

Top 20 Chinese lithium battery separator manufacturers (operation, technologies, markets, production and marketing trends);

Top 20 Chinese lithium battery separator manufacturers (operation, technologies, markets, production and marketing trends);

Top 9 Global lithium battery separator manufacturers (operation, technologies, markets, production and marketing trends).

Top 9 Global lithium battery separator manufacturers (operation, technologies, markets, production and marketing trends).

1. Introduction to Lithium Battery Separator

1.1 Properties and Application

1.2 Classification

2. Lithium Battery Separator Production Preparation and Technical Performance

2.1 Base Material

2.1.1 Polyolefin

2.1.2 Non-woven Fabrics

2.1.3 Ceramic Coating

2.2 Production Technique

2.2.1 Wet Process

2.2.2 Dry Process

2.2.3 Comparison of Production Techniques

2.3 Key Technical Indices

2.3.1 Porosity

2.3.2 Air Permeability

2.3.3 Electrolyte Uptake

2.3.4 Aperture Size and Distribution

2.3.5 Mechanical Property

2.3.6 Automatic Shutdown Protection Performance

2.3.7 Thermal Shrinkage

2.4 Development Orientation of Technology

3. Global Lithium Battery Separator Industry

3.1 Global Lithium Battery Separator Market

3.1.1 Market Demand

3.1.2 Market Size

3.1.3 Product Price

3.2 Global Lithium Battery Separator Companies

3.2.1 Market Share

3.2.2 Technique and Capacity

3.2.3 Supply Relationship

4. China Lithium Battery Separator Industry

4.1 China Lithium Battery Separator Market

4.1.1 Market Demand

4.1.2 Homemade/Imported Separator

4.1.3 Market Size

4.1.4 Product Price

4.2 Chinese Lithium Battery Separator Companies

4.2.1 Market Share

4.2.2 Technique and Capacity

4.2.3 Supply Relationship

5. Global and China Lithium Battery Industry

5.1 Global Demand for Lithium Battery

5.1.1 Demand for Ordinary 3C Lithium Battery

5.1.2 Demand for Power Lithium Battery

5.1.3 Lithium Battery Shipment

5.1.4 Lithium Battery Market Size

5.2 China’s Demand for Lithium Battery

5.2.1 Demand for Power Lithium Battery

5.2.2 Lithium Battery Shipment

5.2.3 Lithium Battery Market Size

5.3 Major Lithium Battery Manufacturers

5.3.1 Market Share

5.3.2 Power Battery

6. Global Li-ion Battery Separator Manufacturers

6.1 Asahi KASEI

6.1.1 Profile

6.1.2 Technology & Technique

6.1.3 Layout in China

6.1.4 Production and Marketing Network

6.1.5 Capacity and Output

6.2 Toray

6.3 UBE

6.3.1 Profile

6.3.2 Technology & Technique

6.3.3 Production and Marketing Network

6.3.4 Capacity and Output

6.4 SKI

6.4.1 Profile

6.4.2 Technology & Technique

6.4.3 Capacity and Output

6.4.4 Customers

6.5 Entek

6.6 Mitsubishi Chemical

6.6.1 Profile

6.6.2 Technology & Technique

6.7 Sumitomo Chemical

6.8 Evonik Industries

6.9 W-Scope

6.9.1 Profile

6.9.2 Operation

6.9.3 Gross Margin

6.9.4 Capacity and Output

7. Chinese Li-ion Battery Separator Manufacturers

7.1 Xinxiang Zhongke Science and Technology (GREEN) Co., Ltd.

7.1.1 Profile

7.1.2 Technology & Technique

7.1.3 Capacity and Output

7.2 Shenzhen Senior Technology Material Co., Ltd

7.2.1 Profile

7.2.2 Operation

7.2.3 Technology & Techique

7.2.4 Capacity and Output

7.2.5 Customers

7.3 Foshan Jinhui Hi-tech Optoelectronic Material Co., Ltd

7.3.1 Profile

7.3.2 Operation

7.3.3 Technology & Technique

7.3.4 Capacity and Output

7.4 Cangzhou Mingzhu Plastic Co., Ltd

7.4.1 Profile

7.4.2 Operation

7.4.3 Gross Margin

7.4.4 Technology & Technique

7.4.5 Capacity and Output

7.4.6 Customers

7.4.7 Forecast and Outlook

7.5 Jiangxi Xian Cai Nanofibers Technology Co., Ltd.

7.5.1 Profile

7.5.2 Operation

7.5.3 Technology & Technique

7.5.4 Investment Plan

7.6 Chongqing Yuntianhua Newmi Technological Co,.Ltd

7.6.1 Profile

7.6.2 Operation

7.6.3 Technology & Technique

7.6.4 Customers

7.6.5 Capacity and Output

7.7 Suzhou GreenPower New Energy Materials Co., Ltd.

7.7.1 Profile

7.7.2 Operation

7.7.3 Technology & Technique

7.3.4 Customers

7.3.5 Capacity and Output

7.8 YiTeng New Energy Technology Co., Ltd.

7.8.1 Profile

7.8.2 Operation

7.8.3 Technology & Technique

7.8.4 Customers

7.8.5 Capacity

7.9 Liaoyuan Hongtu LIBS Technology Co., Ltd.

7.9.1 Capacity

7.9.2 Operation

7.9.3 Technology & Technique

7.9.4 Customers

7.9.5 Capacity and Sales

7.10 Shanghai Energy New Materials Technology Co., Ltd

7.10.1 Profile

7.10.2 Operation

7.10.3 Technology & Technique

7.10.4 Customers

7.10.5 Capacity and Output

7.11 Henan Huiqiang new energy material technology Corp., Ltd.

7.11.1 Profile

7.11.2 Operation

7.11.3 Technology & Technique

7.11.4 Customers

7.11.5 Capacity and Output

7.12 Tianjin DG Membrane Tech. Co., LTD.

7.12.1 Profile

7.12.2 Operation

7.12.3 Technology & Technique

7.12.4 Capacity and Output

7.13 Foshan Donghang Optic-Electric Technology Co., Ltd

7.13.1 Profile

7.13.2 Technology & Technique

7.13.4 Capacity and Output

7.14 Foshan Yingbolai Technology Co.,Ltd.

7.14.1 Profile

7.14.2 Operation

7.14.3 Technology & Technique

7.14.4 Customers

7.14.5 Capacity

7.15 Xucheng (Fujian)Technology Co.,Ltd.

7.15.1 Profile

7.15.2 Operation

7.15.3 Technology & Technique

7.15.4 Customers

7.15.5 Capacity

7.16 Hebei Gellec New Energy Science&Technology Co.,Ltd.

7.16.1 Profile

7.16.2 Operation

7.16.3 Technology & Technique

7.16.4 Capacity and Output

7.16.5 Customers

7.17 Sinoma Science & Technology Co., Ltd.

7.18 Zhejiang Great Southeast Co., Ltd

7.19 Jiangsu Jiujiujiu Technology Co., Ltd.

7.20 Nantong Tianfeng New Electronic Materials Co., Ltd.

8. Development Trend of Lithium Battery Separator

Working Principles of Li-ion Battery

Polyolefin Separator Structure and Features

Characteristics of Non-woven Fabric Separator Technology and Typical Companies

Improvement of High Temperature Resistance of Ceramic Coated Separator

Micrograph of Wet Process PE Separator

Micrograph of Dry Process PP Separator

Structure and Features of Lithium Battery Separator with Varied Production Techniques

Comparison: Investment Costs of Wet Process and Dry Process in China

Comparison: Air Permeability of Different Separators

Aperture Distribution of Separators with Different Preparation Methods

Comparison: Tensile Strength of Different Separators

Comparison: Puncture Strength of Different Separators

Comparison: Automatic Shutdown Performance of Different Separators

Comparison: Thermal Shrinkage of Different Separators

Comparison of Performance between Wet Process Separator and Dry Process Separator

Comparison of Physical Property Indicators between Conventional Separator and Coated Separator

Common Electronics and Automobiles’ Consumption of Lithium Battery Separator

Global Production of Lithium Battery Separator, 2007-2016

Global Production of Ordinary and High-performance Lithium Battery Separator, 2008-2016

Global Production of Ordinary and High-performance Lithium Battery Separator, 2017-2022E

Global Lithium Battery Separator Market Size, 2008-2016

Global Lithium Battery Separator Market Size, 2017-2022E

Average Price of Global Lithium Battery Separator, 2008-2016

Market Share of World’s Lithium Battery Separator Enterprises by Shipment, 2015

Techniques process of International Lithium Battery Separator Manufacturers

Supply Relationship of International Lithium Battery Separator Manufacturers

Supply Relationship of International Power Lithium Battery Separator Manufacturers

China’s demand of Lithium Battery Separator, 2009-2016

China’s Local Production of Lithium Battery Separators, 2009-2016

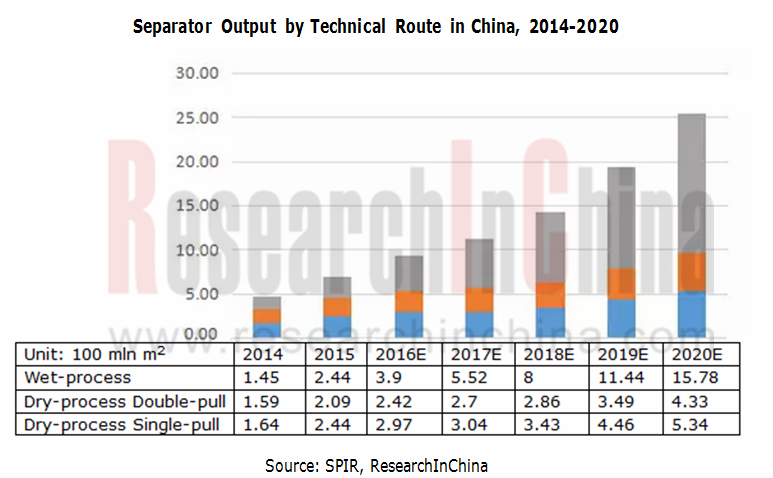

China’s Separator Output (by Technical Route), 2014-2020E

China’s Lithium Battery Separator Demand, 2017-2020E

Proportion of Chinese High-performance Lithium Battery Separator Shipment in Global Total, 2010-2016

Localization Rate of Lithium Battery Separators in China, 2009-2016

China's Lithium Battery Separator Import Structure, 2016

Market Size of Home-made and Imported Lithium Battery Separators in China, 2009-2016

Market Size of Home-made and Imported Lithium Battery Separators in China, 2017-2022E

Quarterly Average Price of Lithium Battery Separators (by Technical Route), 2014-2016

Average Price of Home-made and Imported Separators in China, 2009-2016

Comprehensive Comparison of Major Domestic Battery Separator Enterprises

Ranking by Domestic Lithium Battery Separator Sales, 2016 (10k m2)

Dry-process Separator Sales of Major Domestic Separator Enterprises, 2016 (100 mln m2)

Wet-process Separator Sales of Major Domestic Separator Enterprises, 2016

Dry-process/Wet-process Separator Capacity of Domestic Separator Enterprises by the End of 2016

Capacity and Planned Capacity of Major Domestic Separator Enterprises, 2016

Supply Relationship of Chinese Lithium Battery Separator Manufacturers, 2016

Applications of Li-ion Battery

Global Shipment of Notebook PC, Tablet Computer and Mobile Phone, 2012-2016

Global Shipment of Lithium Batteries for Laptop, Tablet PC and Mobile Phone, 2012-2016

Global Sales Volume of Electric Passenger Vehicle, 2008-2016

Battery Capacity and Cruising Ability of Global Key Electric Vehicles

Global Shipment of Lithium Battery, 2008-2016 (MWh)

Structure (%) of Global Demand for Lithium Battery, 2012-2016

Global Shipment of Lithium Battery by Demand, 2008-2016E (MWh)

Global Lithium Battery Industry Scale, 2008-2016

Estimated Global Power Lithium Battery Market Scale, 2015-2020E

Electric Vehicle (including Passenger and Commercial Vehicle) Production in China, 2008-2016

Electric Vehicle (Passenger Car/Bus/Special Vehicle) Sales Volume in China, 2015-2020E

Proportion of China’s Sales Volume of Electric passenger Vehicle in Global Total, 2013-2016

China Lithium Battery Industry Scale, 2008-2016

China Power Lithium Battery (For xEV) Industry Scale, 2008-2016

Total Demand of Lithium Battery in China, 2015-2020

Competition Pattern of Global Lithium Battery (by Sales Volume), 2016

Rank of Global Top20 Lithium Battery Enterprises by Sales, 2016

Rank of Top10 Power Lithium Battery Enterprises in China, 2016

Global Top20 Passenger Car Lithium Battery Enterprises, 2016

The Joint-stock Suppliers of Power Lithium Battery in the World

Operating Revenue Structure of Asahi Kasei, FY2016

Battery Separator Brands of Asahi Kasei

Development Course of Hipore

Development Course of Celgard

Development Course of Daramic

Battery Separator Micrograph of Asahi Kasei

Technical Parameters of Celgard’s Battery Separator

Product R&D and Production Plan of Celgard

Layout of Asahi Kasei in China

Administrative Organizations of Asahi Kasei (China)

Lithium Battery Separator Production Bases of Asahi Kasei (including Celgard & Daramic)

Lithium Battery Separator Capacity Release of Asahi Kasei, 2004-2016

Contact Means of Battery Separator Marketing Division of Asahi Kasei

Lithium Battery Separator Capacity Planning of Asahi Kasei, 2016-2020E

Battery Separator Output, Capacity and Capacity Utilization of Asahi Kasei, 2008-2016

Battery Separator Output, Capacity and Capacity Utilization of Celgard, 2008-2016

Battery Separator Output, Capacity and Capacity Utilization of Toray Tonen, 2008-2013

Business Performance of UBE, Sep.FY2009-FY2016

Operating Revenue Structure of UBE, FY2013/14

Contact Means of Battery Separator Business Division of UBE

Battery Separator (Japan) Production Bases of UBE

Battery Separator Output, Capacity and Capacity Utilization of UBE, 2010-2018E

Key Subsidiaries under SKI

Battery Separator Output, Capacity and Capacity Utilization of SKI, 2010-2018E

Contact Means of Battery Separator Business Division of Entek

Technical Parameters of Entek’s Battery Separator

ENTEK “wet” process separator compared to (B) competitor “dry” process separator

Operating Revenue Structure of Mitsubishi Chemical, FY2016

Global Branches of Mitsubishi Chemical

Lithium Battery Separator Manufacturing Techniques of Mitsubishi Chemical

Operating Revenue Structure of Sumitomo Chemical, FY2013/14

Technical Performance of Lithium Battery Separator of Sumitomo Chemical

Punctuation Performance of Sumitomo Chemical’s Lithium Battery Separator

Sumitomo Chemical’s Separator Manufacturing Sites

Global Branches of Sumitomo Chemical’s Electronic Materials Division

Development Course of Evonik Litarion GmbH

Properties of Evonik's SEPARION? separator

Evonik's SEPARION? Separator Manufacturing Technologies

Business Performance of W-Scope, 2009-2016

Battery Separator Marketing Regions of W-Scope, 2016

Gross Margin of W-Scope’s Battery Separator, 2009-2016

W-Scope’s WSK Plant Site Layout

W-Scope’s Chungju Plant

Capacity Investment Plan of W-Scope, 2016-2018

Production Bases of W-Scope

Battery Separator Output, Capacity and Capacity Utilization of W-Scope, 2011-2018E

Technical Parameters of GRE-P Series Separator of Xinxiang Zhongke Science and Technology (GREEN)

Technical Parameters of GRE-T Series Separator of Xinxiang Zhongke Science and Technology (GREEN)

Technical Parameters of GRE-H Series Separator of Xinxiang Zhongke Science and Technology (GREEN)

Lithium Battery Separator Output, Capacity and Capacity Utilization of Xinxiang Zhongke Science and Technology (GREEN), 2007-2016

Business Performance of Shenzhen Senior, 2012-2017Q1

Global Marketing Network of Shenzhen Senior Technology Material

Wet Process and Dry Process Lithium Battery Separator Micrograph of Shenzhen Senior Technology Material

Special Lithium Battery Separator Micrograph of Shenzhen Senior Technology Material

Major Products and Clients of Shenzhen Senior

Yield of Products Shenzhen Senior Technology Material Sold to LG Chem, 2013-2016H1

Revenue Share of Downgraded and Waster Separators of Shenzhen Senior Technology Material, 2013-2016H1

Capacity Utilization of Shenzhen Senior, 2012-2016

Capacity and Output of Separator (Dry-process/Wet-process) of Shenzhen Senior, 2012-2017

Revenue Contribution of Shenzhen Senior’s Top 4 Customers, H1 2016

Major Customers for Lithium Battery Cell of Shenzhen Senior Technology Material

Business Performance of Foshan Jinhui Hi-tech Optoelectronic Material, 2009-2016

Technical Parameters of Ordinary Lithium Battery Separator of Foshan Jinhui Hi-tech Optoelectronic Material

Technical Parameters of Strengthened Lithium Battery Separator of Foshan Jinhui Hi-tech Optoelectronic Material

Lithium Battery Separator Investment and Production Expansion Plan of Foshan Jinhui Hi-tech Optoelectronic Material

Lithium Battery Separator Output, Capacity and Capacity Utilization of Foshan Jinhui Hi-tech Optoelectronic Material, 2011-2016

Business Performance of Cangzhou Mingzhu Plastic, 2009-2017Q1

Operating Revenue Structure of Cangzhou Mingzhu Plastic, 2012-2016

Gross Margin of Main Business of Cangzhou Mingzhu Plastic, 2009-2016

Gross Margin Structure of Cangzhou Mingzhu Plastic by Product, 2012-2016

Typical Performance Index of Dry Process Separator of Cangzhou Mingzhu Plastic

Typical Performance Index of Wet Process Separator of Cangzhou Mingzhu Plastic

Lithium Battery Separator Production & Sales and Average Price of Cangzhou Mingzhu Plastic, 2012-2016

Lithium Battery Separator Output, Capacity and Capacity Utilization of Cangzhou Mingzhu Plastic, 2012-2016

Lithium Battery Separator Revenue and Sales of Cangzhou Mingzhu Plastic, 2017-2019E

Equity Structure of Jiangxi Xian Cai Nanofibers Technology

Operation of Jiangxi Xian Cai Nanofibers Technology, 2012-2014

Technical Parameters of Polyimide (PI) Nano Battery Separator of Jiangxi Xian Cai Nanofibers Technology

Polyimide (PI) Nano Battery Separator Investment Plan of Jiangxi Xian Cai Nanofibers Technology

Business Performance of Yuntianhua Newmi, 2012-2016

Yuntianhua Newmi’s Revenue from Top 5 Clients and % of Total Revenue, 2015

Capacity, Output and Capacity Utilization of Yuntianhua Newmi by Products, 2015-2016

Revenue and Net Income of Suzhou GreenPower, 2014-2016

R&D System of Suzhou GreenPower

Product Specification of Suzhou GreenPower’s Lithium-ion Battery Separator for Consumer Electronics

Product Specification of Suzhou GreenPower’s Ultra-thin Lithium-ion Battery Separator

Lithium Battery Separator Output, Capacity and Capacity Utilization of Suzhou GreenPower, 2014-2018E

Revenue and Net Income of YiTeng New Energy, 2012-2016H1

SEM Images of YiTeng New Energy’s Products

Business Performance of Liaoyuan Hongtu, 2015-2017

Revenue Structure of Liaoyuan Hongtu, 2016

Gross Margin of Liaoyuan Hongtu by Product, 2015-2017

R&D Cost of Liaoyuan Hongtu, 2014-2016

Revenue and Proportion of Top Five Clients of Liaoyuan Hongtu, 2015-2016

Revenue Structure of Top Five Clients of Liaoyuan Hongtu, Jan.-Apr.2017

Sales Volume and Unit Price of Liaoyuan Hongtu (By Product), 2015-2017

Business Performance of SEMCORP, 2015-2017

Revenue and Cost of SEMCORP, 2015-2016

Lab Equipment of SEMCORP

Product Specificaiton of SEMCORP’s Base Separator

Revenue from Top Five Clients of SEMCORP, 2016

Revenue from Top Five Clients of SEMCORP, 2015

Capacity and Output of SEMCORP by Product, 2015-2016

Sales Volume and Unit Price of SEMCORP by Product, 2015-2016

Progress Planning of Seven Production Lines of SEMCORP

Revenue and Net Income of Huiqiang New Energy, 2013-2016

Comparison of Key Technical Indicators of Separators of Huiqiang New Energy and Celgard

Revenue of Huiqiang New Energy from Top 5 Clients and % of Total Revenue, 2016

Revenue of Huiqiang New Energy from Top 5 Clients and % of Total Revenue, 2015

Output and Capacity of Huiqiang New Energy, 2013-2016

Sales Volume and Average Price of Huiqiang New Energy , 2015-2016

Revenue and Net Income of Tianjin DG Membrane,2016-2017

Technical Index of Tianjin DG Membrane’s Thermal-Bonding Double-Side Blend Coating Composite Membrane (D12P2P2)

Separator Capacity and Output of Tianjin DG Membrane, 2013-2017

Technical Parameters of Conventional Separator (Uniaxial Tensile Dry Process PP Lithium-ion Battery Separator) of Foshan Donghang Optic-Electric

Separator Capacity and Output of Foshan Donghang Optic-Electric, 2013-2017E

Revenue and Net Income of Foshan Yingbolai Technology, 2014-2016

Key Parameters of Four-layer Composite Separator of Foshan Yingbolai Technology

Foshan Yingbolai Technology‘s Revenue from Top5 Clients and % of Total Revenue, 2015

Revenue and Net Income of Xucheng Technology, 2014-2016

Key Technical Indicators of Xucheng Technology’s Coated Separators

Revenue of Xucheng Technology from Top 5 Clients and % of Total Revenue, 2015

Revenue of Xucheng Technology from Top 5 Clients and % of Total Revenue, 2016

Revenue of Hebei Gellec New Energy Science & Technology, 2013-2016

Revenue Structure of Hebei Gellec New Energy Science & Technology, 2014-2016

Characteristics of Lithium-ion Power Battery Separator of Hebei Gellec New Energy Science & Technology

Characteristic Parameters of Lithium-ion Power Battery Separator of Hebei Gellec New Energy Science & Technology

Lithium Battery Separator Capacity of Hebei Gellec New Energy Science & Technology, 2014-2017E

Main Clients of Hebei Gellec New Energy Science & Technology, 2016

Lithium Battery Separator Investment Plan of Sinoma Science & Technology

Lithium Battery Separator Investment Plan of Zhejiang Great Southeast

Lithium Battery Separator Investment Plan of Jiangsu Jiujiujiu Technology

Technical Parameters of Lithium Battery Separator of Nantong Tianfeng New Electronic Materials Co., Ltd.

Development Trend of Lithium Ion Battery

Autonomous Driving Domain Controller and Central Computing Unit (CCU) Industry Report, 2025

Research on Autonomous Driving Domain Controllers: Monthly Penetration Rate Exceeded 30% for the First Time, and 700T+ Ultrahigh-compute Domain Controller Products Are Rapidly Installed in Vehicles

L...

China Automotive Lighting and Ambient Lighting System Research Report, 2025

Automotive Lighting System Research: In 2025H1, Autonomous Driving System (ADS) Marker Lamps Saw an 11-Fold Year-on-Year Growth and the Installation Rate of Automotive LED Lighting Approached 90...

Ecological Domain and Automotive Hardware Expansion Research Report, 2025

ResearchInChina has released the Ecological Domain and Automotive Hardware Expansion Research Report, 2025, which delves into the application of various automotive extended hardware, supplier ecologic...

Automotive Seating Innovation Technology Trend Research Report, 2025

Automotive Seating Research: With Popularization of Comfort Functions, How to Properly "Stack Functions" for Seating?

This report studies the status quo of seating technologies and functions in aspe...

Research Report on Chinese Suppliers’ Overseas Layout of Intelligent Driving, 2025

Research on Overseas Layout of Intelligent Driving: There Are Multiple Challenges in Overseas Layout, and Light-Asset Cooperation with Foreign Suppliers Emerges as the Optimal Solution at Present

20...

High-Voltage Power Supply in New Energy Vehicle (BMS, BDU, Relay, Integrated Battery Box) Research Report, 2025

The high-voltage power supply system is a core component of new energy vehicles. The battery pack serves as the central energy source, with the capacity of power battery affecting the vehicle's range,...

Automotive Radio Frequency System-on-Chip (RF SoC) and Module Research Report, 2025

Automotive RF SoC Research: The Pace of Introducing "Nerve Endings" such as UWB, NTN Satellite Communication, NearLink, and WIFI into Intelligent Vehicles Quickens

RF SoC (Radio Frequency Syst...

Automotive Power Management ICs and Signal Chain Chips Industry Research Report, 2025

Analog chips are used to process continuous analog signals from the natural world, such as light, sound, electricity/magnetism, position/speed/acceleration, and temperature. They are mainly composed o...

Global and China Electronic Rearview Mirror Industry Report, 2025

Based on the installation location, electronic rearview mirrors can be divided into electronic interior rearview mirrors (i.e., streaming media rearview mirrors) and electronic exterior rearview mirro...

Intelligent Cockpit Tier 1 Supplier Research Report, 2025 (Chinese Companies)

Intelligent Cockpit Tier1 Suppliers Research: Emerging AI Cockpit Products Fuel Layout of Full-Scenario Cockpit Ecosystem

This report mainly analyzes the current layout, innovative products, and deve...

Next-generation Central and Zonal Communication Network Topology and Chip Industry Research Report, 2025

The automotive E/E architecture is evolving towards a "central computing + zonal control" architecture, where the central computing platform is responsible for high-computing-power tasks, and zonal co...

Vehicle-road-cloud Integration and C-V2X Industry Research Report, 2025

Vehicle-side C-V2X Application Scenarios: Transition from R16 to R17, Providing a Communication Base for High-level Autonomous Driving, with the C-V2X On-board Explosion Period Approaching

In 2024, t...

Intelligent Cockpit Patent Analysis Report, 2025

Patent Trend: Three Major Directions of Intelligent Cockpits in 2025

This report explores the development trends of cutting-edge intelligent cockpits from the perspective of patents. The research sco...

Smart Car Information Security (Cybersecurity and Data Security) Research Report, 2025

Research on Automotive Information Security: AI Fusion Intelligent Protection and Ecological Collaboration Ensure Cybersecurity and Data Security

At present, what are the security risks faced by inte...

New Energy Vehicle 800-1000V High-Voltage Architecture and Supply Chain Research Report, 2025

Research on 800-1000V Architecture: to be installed in over 7 million vehicles in 2030, marking the arrival of the era of full-domain high voltage and megawatt supercharging.

In 2025, the 800-1000V h...

Foreign Tier 1 ADAS Suppliers Industry Research Report 2025

Research on Overseas Tier 1 ADAS Suppliers: Three Paths for Foreign Enterprises to Transfer to NOA

Foreign Tier 1 ADAS suppliers are obviously lagging behind in the field of NOA.

In 2024, Aptiv (2.6...

VLA Large Model Applications in Automotive and Robotics Research Report, 2025

ResearchInChina releases "VLA Large Model Applications in Automotive and Robotics Research Report, 2025": The report summarizes and analyzes the technical origin, development stages, application cases...

OEMs’ Next-generation In-vehicle Infotainment (IVI) System Trends Report, 2025

ResearchInChina releases the "OEMs’ Next-generation In-vehicle Infotainment (IVI) System Trends Report, 2025", which sorts out iterative development context of mainstream automakers in terms of infota...